- Blow Moulding

- Extrusion

- Injection Moulding

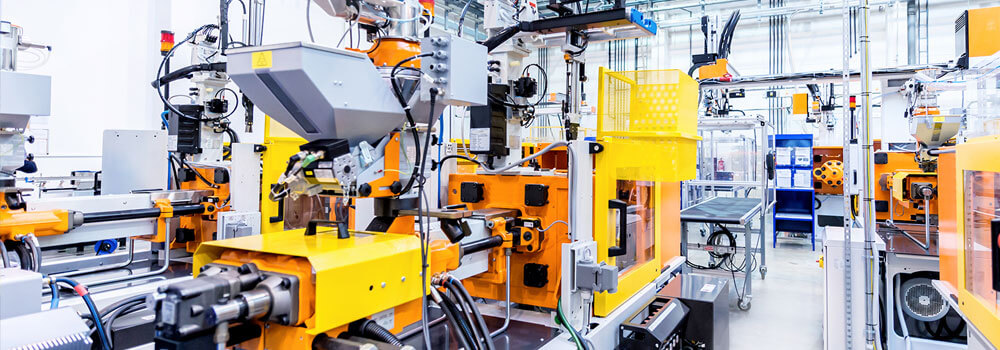

At Sabin, we believe in technological versatility, ensuring that our clients, both domestic as well as international, receive accurate advice ideally tailored to their individual plastic packaging needs. Our CMM machines inspect products to ensure 100% precise results. What’s more, we continually invest in the latest technology to remain at the forefront of automation and overall capabilities.

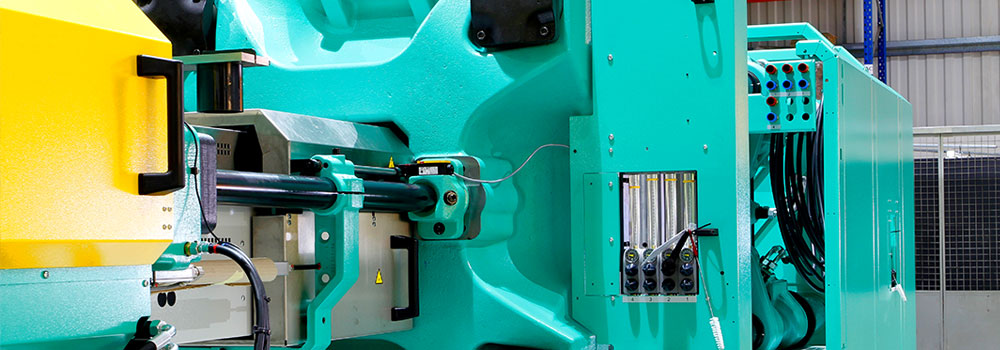

We uses state-of-the-art micro-processor controlled injection moulding machines from world-renowned companies and offers advanced solutions like cube technology, two component moulding, in-mould closing, and robot-assist to successfully meet customer requirements.

- Central material loading system.

- Master batch dosing units for colour steadiness.

- Tooling and tool maintenance systems with modern CAD-CAM technology and high-precision CNC machines including EDM and 4-axis milling.

- Up to date IT infrastructure including ERP setup for sophisticated planning.

- Computerised shop-floor monitoring system with Machine Data Transducer units connected with each machine and equipment for acceleration of the information exchange process between machines and ERP systems.

Sabin Acrylic Fabrication Industry welcomes any enquiry and will be pleased to work with you to develop your project requirements, or Sabin will be pleased to provide you a turnkey project, from design and engineering, to full Commissioning.

“We remain prepared and welcome your Contact and detail.”

We’ll update you with the PDF